Nowadays, there are so many new and modern technologies in manufacturing and massive production. An important aspect of achieving the highest quality product on the market – is passing through certain development phases. One of the most important phases in this process – is the development of product prototypes. But, what are the most common ways to develop and manufacture a product and its prototype? We will try to point out 5 of them in this text.

Product Development

The growth of companies, especially manufacturing companies – is achieved by constantly finding and launching new products, as well as modifying the existing ones. The product development process is very important because all the other characteristics that follow its completion – are depending on the quality of that process. This is primarily about competitiveness. Within the product development – certainly, the most important place is occupied by the prototype development phase. This phase involves making a model of the desired product.

What Should Prototype Look Like?

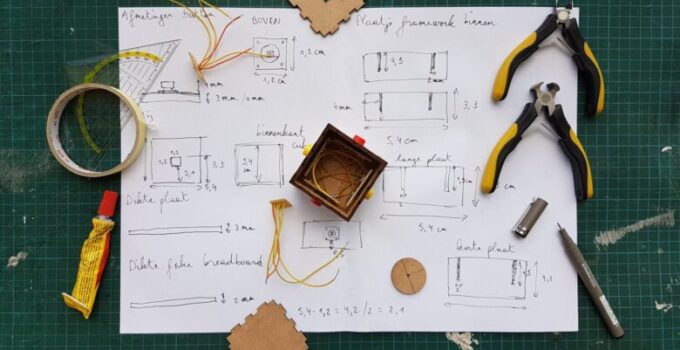

img source: pexels.com

The prototype must be representative, with the ability to test quality, features, and characteristics. When making products of more complex geometry and shape – the classic methods of prototyping are a limiting factor. As a result of increasingly complex technological requirements, technologies for the rapid production of product prototypes using additive methods have been developed. Today, with the development of modern technology, the production of prototypes has been perfected. In addition to a large number of prototyping techniques available today – a significant place is occupied by modern printing techniques.

What Is A Prototype?

A prototype is the first or original copy of something that is or will be reproduced or developed. However, given the wide use of the term prototype in practice – the following more comprehensive definition can be taken: A prototype is the first, original form, or type of product intended for various types of testing and testing for later production and use. Depending on the characteristics of the prototype itself – its subsequent mass production, as well as implementation and marketing, will depend.

Ways Of Developing And Manufacturing A Prototype

1. Make A Difference Between A Prototype And A Final Product

It is very important to know the difference between the prototype and the final product. There are three basic differences we should take into consideration:

img source: pexels.com

- Materials

In the case of prototype production, the materials used to produce them generally represent a substitution – similar to the real materials from which the product will be made. Besides, the materials used to make the final products require manufacturing processes that involve greater investment than is the case of prototyping

- Processes

Expensive and time-consuming unique manufacturing processes are required in the production of final products. On the other hand, when making prototypes, more flexible processes are used.

- Quality and accuracy of manufacturing

Final products require precise and accurate production of all product details, which requires significant effort and cost – while prototypes do not.

2. Product development

img source: pexels.com

The process of developing a new product is a complex project that includes a large number of phases and individual activities. Today, customers are looking for smaller and smaller quantities of products in a variable range in the shortest possible time. This requires manufacturers to constantly monitor the market situation and to respond quickly to consumer demands. For example, in the production of injection plastic molds, we have market demands such as increased quality, more affordable prices, and a shorter time for innovation and product development. Click here to see how modern companies engage all their creative potentials to find new opportunities to achieve these goals.

3. Industrial design and development

Industrial design is a very important component of development. Experts who have experience in this field and work in a design team – design the product in a functional way. This will also allow users who will eventually use the finished product to be easy to use. Design can be done in several ways – sketching, 3D modeling, 3D printing, prototyping, testing, etc. With the newer generation, 3D software, very realistic visualizations of new products can be created.

- Using 3D technology

Simple prototyping, for example, using the 3D printing method, has revolutionized the product design process. The ability to materialize design visions into physical objects within a few hours not only speeds up the production process but also means that designers have more time and opportunities to perfect the design before production. No matter what we design, we will rarely achieve the final look of the product from the first. Rigorous testing, evaluations, and tweaks are the best way to assess what works and what doesn’t.

4. Rapid prototyping

img source: pexels.com

The term rapid prototyping (RP) refers to a series of similar production processes, which are automated, based on control instructions created directly from CAD (Computer-aided design) files or other digital data, without the use of tools, accessories, without the need for additional mechanical operations, and produce physical objects. Although it contains the prefix fast in its phrase, this adjective is relative, since prototyping with this method takes 3-72 hours. But, compared to the time required to produce an identical physical object by conventional approaches, the adjective acquires its full meaning.

5. Prototype testing

The most important phase of product development is the production and testing of prototypes. Testing is enabling the verification of the adequacy of the product before starting the production. As prototyping is expensive, new technologies for rapid prototyping have been developed as well as modern software for designing virtual prototypes. Virtual Prototyping (VP) are partially or completely, eliminating the fabrication and testing of physical prototypes. The scientific goal of the research is to identify key parameters that affect the shortening of the time of prototype development of a new product and quantification of the impact of these parameters on the development time, development costs, and product quality.

Conclusion

We are witnessing that technology is advancing and developing at high speed – and that traditional methods of prototyping are increasingly losing their importance. Therefore, the best and highest quality way to make a prototype is the so-called rapid prototyping technology. If manufacturing companies want to progress, develop, and become competitive in the market, they should keep up with the technology and apply it. One of the most commonly used methods for fast, modern, prototyping today is certainly 3D printing.