All items, gadgets, and devices that are technologically advanced are better than their previous models. The same goes for the old, rigid printed circuit boards that are the only reliable part needed to make electronic devices. And since the technology behind flexible PCB is getting improved daily, you might be wondering what is the importance of these components.

If you are thinking about whether or not you should use these components in your manufacturing plant, this article might help you. The text below is going to feature a list of the reasons why it is important to use flexible circuit boards for your business. Let’s take a closer look:

1. They Can Improve Flexibility

Image source: pexels.com

Did you ever wonder why the designers behind these boards decided to make them bendable? Well, one of the reasons PCB manufacturers did this is because they were looking for ways to save space while boosting flexibility at the same time. This invention is what has led to a wide range of devices to become smaller and portable.

Additionally, by implementing flexible circuit boards, they managed to reduce the time needed for assembling the entire device. This means that they can further increase the reliability of the machine. Without them, it would not be possible to have such small devices as we have today.

2. Easy to Pack And Store

If you choose a traditional PCB, you’ll need to pack it in a unique way. The size of the box will mostly rely on the shape and size of the board. This means that it can be quite difficult to customize the packaging for each machine part, and manufacturers need to have a specific way of storing those items.

But, with a flexible circuit board, it can basically fit wherever you want it to. Various studies show that they can save more than 55 percent of space and weight when compared to other options, which means that you can save both time and money by choosing flexible printed circuit boards.

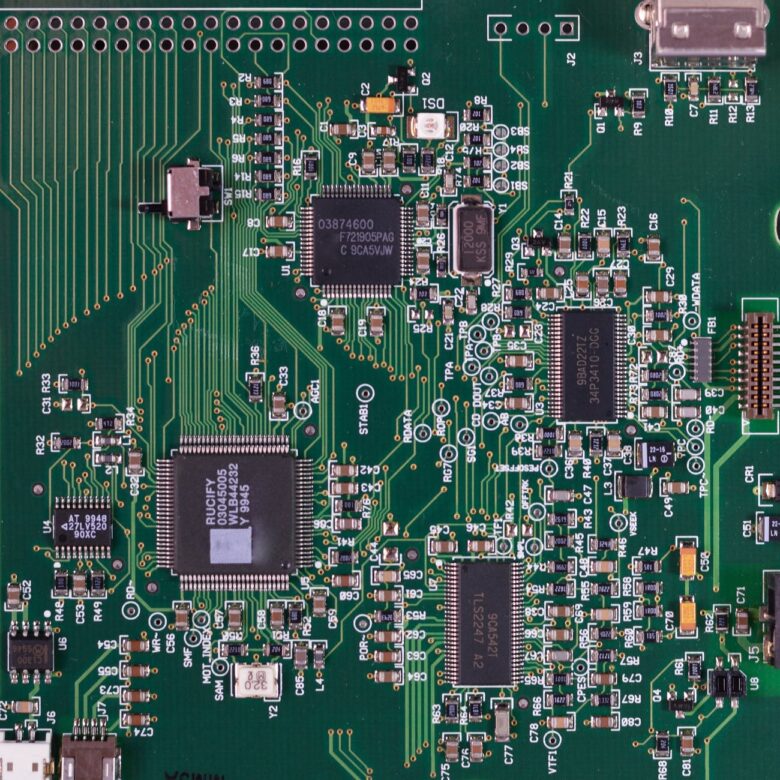

3. The Performance is Better

Image source: pexels.com

As mentioned at the beginning of this article, any device that is new and innovative is better than its previous model, and the same goes for flexible circuits. They often feature a low dielectric constant, which means that they can easily transmit electrical signals through the device – something that cannot be said for rigid boards.

Additionally, they have amazing thermal characteristics, something that allows the device to cool down quickly and easily. Also, the melting point allows the parts to operate well, even if the temperatures get high. If you are interested in seeing more info about these flexible circuit boards, you can check this website out.

4. The Assembly And Output Are More Reliable

Flex boards have better assembly reliability and output than other boards. The traditional ones reduce the hardware needed in order to connect the interior parts. During the assembly process, flexible circuit boards will lower the chances and risks of the components getting dislocated. This is a situation that most commonly happens when the interconnecting parts and systems become too complex for several parts. But, with flex PCBs, you can entirely take away those risks.

5. Entirely Bendable

Image source: pexels.com

As stated, you’ll be able to move, bend, pack, and store the boards without worrying about damaging them. They feature various outlines and it is possible for them to fit any container, box, and package that you are thinking about utilizing during different processes.

So, is there any kind of limitations? Well, there is one, it is the board’s volume. It can completely withstand dynamic bending, hence, different industries use it in various parts that need to move all the time. For example, if you manufacture flip phones, by adding a bendable PCB to it, it’ll allow it to open and close as many times as you need it to, without damaging the device or parts inside.

6. It Can Save You a Lot of Time And Money

We already mentioned that it can save you a lot of time during the assembly process, however, it can also save you a lot of money. How, you might be wondering? Well, since you’ll cut down the assembly time, and you’ll have various packaging options, you can actually save a lot of money too.

This will also cut labor expenses, the price of the wires, and the price of generating several purchasing orders. Hence, instead of, for example spending a lot of your budget for something that is not suitable for specific devices, you’ll save money, time, as well as improve the overall quality of your products.

7. Boosted Aesthetics

Image source: pexels.com

If you have been an owner of a company for some time, you must know that the aesthetics of your devices will influence whether or not someone will actually purchase it from you. If you are looking for a way to increase the sale of a particular item, you might want to consider implementing a flexible PCB.

How Can I Choose a Company?

Before we conclude this article, there are a few things that are worth mentioning about choosing a company that will provide you with these boards. Firstly, you’ll want to check the testimonials and reviews of other customers. Yes, you should check them on the official website, however, you should also check the independent sites.

Also, before choosing one, you’ll definitely want to compare the prices and features you can get. What one company offers does not mean that you’ll get the same thing at another company. Hence, ensure that you compare what you are getting for the price you’ll be paying. Doing all of these things will ensure that you choose the best company that can give you the components you need.

Conclusion

As you were able to learn, there is actually a wide range of benefits that you can gain by choosing flexible printed circuit boards, which means that they are quite important in the manufacturing industry. So, now that you know what they are important, as well as the benefits you can gain, you should not lose any more time. Instead, you might want to start looking for companies that can provide you with the best flexible circuit boards on the market!