With the growing industrial economy in most parts of the world, the accuracy and efficiency of measuring raw materials and products take a toll on the improvement of production. Factories require machines and technology that showcase precision and efficiency in terms of cost without sacrificing productivity.

Industries that deal with the measurement of volumetric flow of fluid — liquid, gas, and steam — make use of a special type of measuring device — flow meters. These devices are measuring devices designed and specialized in measuring the stream of a known fluid.

Fluids that pass through open channels such as rivers and streams and close channels such as pipes may be measured with stream gauges. These devices are categorized into two — gas and liquid flow gauge.

Due to variations of fluid in terms of quantity, physical form, rate, temperature, viscosity, and pressure, different stream meters are specialized to cater to such fluid variation. These fluid variations are defined as either the product or the raw material used in industrial application. The following, as listed by SmartMeasurement, will further the understanding of the application of different flow meters in varying industries.

Building Automation

Img source: thomasnet.com

Raw materials like water and energy are examples of what the flow meters measure in building automation. Energy meters can be found in the optimization of chillers, monitoring of hot water consumption, and primary and secondary heat exchanger monitoring. For energy balancing optimization and chemical addition optimization, ultrasonic and electromagnetic flow meters are typically used. Some building automation also make use of thermal meters for the purpose of air handling and hot air measurement.

Chemicals

Measurement of acids and other corrosive materials are done by specialized flow meters namely ultrasonic and all-ceramic electromagnetic stream gauge. To balance out gases and liquids, especially when dealing with huge quantities, industries use mass flow sensors. Such meters are also used in mixing and batching applications where exact volume for recipes is required.

Food and Beverages

As a source of energy for consumers, industries that concern themselves with processing food and beverages use exact amounts of raw materials to produce goods with consistency. The electromagnetic flow indicator is one of the types of these devices used for the measurement of fluids, juices, and water for drinking. For measuring starch solutions and liquefied CO2, Coriolis mass flow meters are utilized.

Power and Utilities

Power, as one of the vital parts of a nation, needs to have accurate calibration to remain steady and sustainable. To produce calibrated and measured flow of fluids in power generation, intrusive ultrasonic flow trackers are utilized for non-conductive plant water feed. Electromagnetic stream sensors are also used in terms of water cooling and heat exchanging.

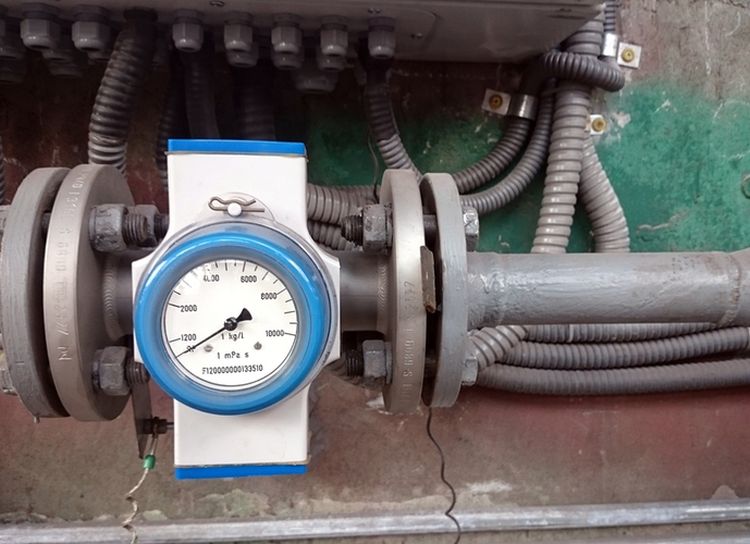

Marine

Img source: hsmsearch.com

Monitoring fuel in ships is done by positive displacement flow meters. In this way, ship crews will know when to refuel. Such meters are utilized in offshore for fueling and refueling, too. Magnetic stream sensors are also used to measure onboard reverse osmosis systems. Liquid flows, especially in seafaring, are monitored through portable ultrasonic meters.

Metals and Mining

To power heavy machinery used in mining, series positive displacement stream sensors monitor the fuel consumption in remote mining applications which do not have external power. Hydro-cyclone feed processes monitoring is carried out by installing series electromagnetic flow sensors. For stream and density measurement, mass flow meters are used especially in smelting furnaces.

Oil and Gas

Oil and gas, as components for power generation, are accurately measured to produce the maximum power while using less raw materials. Industries install positive displacement stream indicators to measure crude and fuel oils. Some also make use of Coriolis flow meter to not only measure well-head oil but also in the monitoring of water amount in crude.

Pharmaceutics

Pharmaceutical industries turn to the usage of these meters when dealing with their production. Especially in hygienic stream systems, non-intrusive stream indicators are used where transducers never intervene in the process stream. For medicine production, where critical and high accuracy measurements should be observed, electromagnetic flow sensors do the job. Pill coating systems are also installed with series thermal mass stram meters.

Pulp and Paper

Img source: esemag.com

The production of paper using the pulp as a raw material requires all-ceramic magnetic flow indicator when dealing with highly abrasive slurries. Installed in pulp and paper facilities are series meters for conductive liquids such as water and lime mud and liquid additives that include bleaches and dyes. Fuels that power burners are also measured by series thermal mass flow meters.

Water and Wastewater

Aside from industrial use, measuring technology is also used for residential purposes. Fluids such as wastewater sludge and raw water are successfully measured through electromagnetic flow sensors. The ultrasonic types of sensors are also used for the same purposes where it increases the accuracy as well as gaining a non-intrusive type of measurement. Open channel sludges are measured through the use of magnetic flow sensor insertion.

Takeaway

Understanding the application and importance of flow meters is crucial in the industrial age. Knowledge about what type of flow sensor to use in certain productions ensures economic growth in the competitive world where accuracy and calibration of measurements become vital indicators in the industry.