If there is one manufacturing process that many industries can’t work without, it’s CNC machining. This method involves the use of computers to control the machine parts. With the multiple benefits it can bring to the table, it is no wonder that almost all industries have adopted this technology, and that includes even small-scale repair shops and workshops.

According to Ltc-proto.com, it is one of the leading companies in the world that offer CNC machining services, whatever your production needs might be; our experts have the technical capability and know-how to bring your ideas into reality.

For those who are curious about the applications of CNC machining, you should read this article. We’ll explain its importance and how it benefits many of these industries. For this post, we are going to have an in-depth look about various aspects of CNC machining and its applications.

What You Need to Know About CNC Machining

Img source: sd3d.com

CNC machining is a type of manufacturing technique that uses pre-programmed computer software, which dictates the movements of machinery and tools. The software can control different machines that range from lathes and grinders to routers and mills. Using single set of commands, this manufacturing process can easily accomplish a three-dimensional cutting task.

The “CNC” in this type of manufacturing process stands for computer numerical control. It replaces manually control of machines, where operators are needed to guide the movements of machining tools with the use of levers, wheels, and buttons. From afar, the system might look like regular set of computers, but the consoles and software programs it uses makes it distinct from other forms of computing.

In much simpler terms, CNC machining is a subtractive process in which raw materials are removed using cutting tools with extreme precision which makes up part of a product.

This procedure is very superior in comparison to manual production ensuring you get high-quality, smooth finishes that will meet all your minimum standards within a suitable budget range.

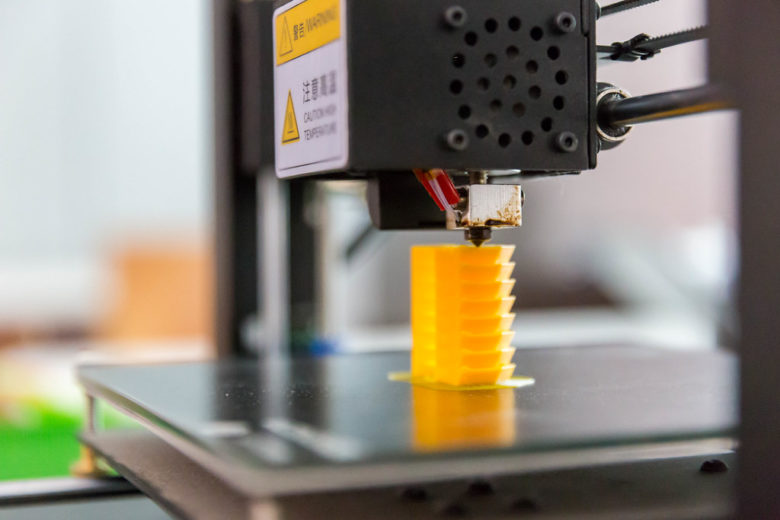

What is the Difference Between CNC Machining and 3D Printing?

Img source: flickr.com

There are many advances in technology and improvements that revolutionize machinery and engineering that gives plenty of options for business. Two of these advancements include CNC machining and 3D printing.

These two manufacturing processes are similar yet different in some aspect. Each of them has unique benefits, but there are varying circumstances where businesses may want to use them depending on availability and cost. Both of them are computer-controlled solutions used in manufacturing products out of material.

They can deliver these products with efficiency and safety that makes them at the forefront. Because the machines are automated, machinists and engineers can make the prototypes with much efficiency as long as they have the design without worrying about human error.

Although 3D printing offers more efficiency, it can only create an item from on smaller scale. When production is needed on a large scale, CNC machining has an advantage over 3D printing. This is because assembly lines are quicker than the 3D printer that builds the products layer by layer. In building large parts, it has an advantage because 3D printing can only make a product that fits the printing bed. In other words, 3D printing cannot replace the role of its in manufacturing mass-produced items.

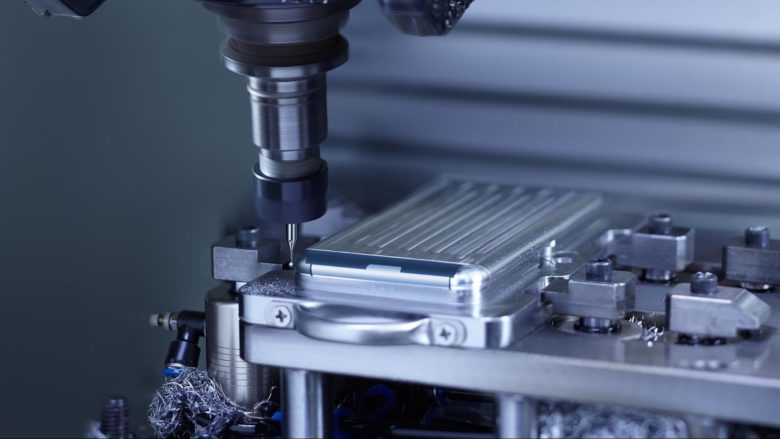

What are the Benefits of Using CNC Machining?

Img source: gatewayfabrication.com

There are plenty of reasons why industries are shifting to this technology. CNC machines have a high degree of automation, which, in turn, could lower the company’s labor costs. It also offers more precision when it comes to producing parts and products with consistency. Aside from being exponentially faster, they are choosing CNC machining for its multi-axis linkage that enables them to create complicated parts and products.

In programing the CNC software, the code generator inside the numerical system always assumes that the mechanisms are flawless despite the possibility of errors. The placement of tools, on the other hand, is outlined in a series of inputs called a part program. Of course, these machines are not perfect, as errors become significant when the machines are simultaneously cutting in more than one direction. But this is minimal compared to manual controls.

Another advantage of CNC machining is the programs are retained in the computer’s memory. Because programmers write the code, they can also edit them. With such capability, the system offers a sizable computational capacity. The systems are also static, which means you can add newer commands to a pre-existing program using a revised code.

Its also very cost effective, it requires little investment especially when it comes to tooling further reducing the cost of the production phase making it easier and profitable to roll out mass production.

Repeatability is one of the most important aspects, after you’ve created a program it becomes easier and efficient to produce similar copies of the master prototype.

Different Applications of CNC Machining

Img source: navitekmachining.com

The earliest application of numerical control machines was in the 1940s when motors are installed to operate the movements of pre-existing tools. The mechanisms are enhanced with the advancement in technologies, and now, digital computers have paved the way for the popularity of CNC machining.

Metal Fabrications

Many industries require metal plates in thin forms like steel plates for parts and products. According to the prototyping expert in China, it requires several fabrication tasks. It includes drilling holes with high precision, plasma or flame cutting, shearing, and welding. All these processes are made more accessible by CNC machines.

Many other industries benefit from metal fabrication using these machines. One of them is the electronics industry. Think about the motherboards and computers with thousands of tiny parts manufactured with precision.

Another industry that benefits from using manufacturing methods in the production of firearms and ammunition. Most of its parts, like the triggers, pins, ammunition clips, barrels, and several other components, are created using this machining process.

Metal Removal Applications

Img source: ebi-part.com

CNC machines are also useful in industries that used metal removal in their techniques. That includes the automotive and aerospace industries and jewelry making. The technique removes excess metal from the raw material to create a designed product.

Aside from its use in subtractive manufacturing, CNC machines can also produce products of complex geometries. Be it a square, rounded, threaded, and even three-dimensional part and these machines can do it with precision and consistency.

In EDM (Electrical Discharge Machining) Applications

Using CNC automation, EDM machines are used to generate sparks that will expend the surplus metal away. There are two ways to do this, by Vertical EDM that uses electrodes of the same size and shape of the cavity that should be carved out, or by Wire EDM, where it uses die and die sets to create a punch.

Woodworking industries use these machines as well as a host of other industries like pharmaceuticals, food, and beverage, among others. It is even used in engraving and lettering systems for hobbyists and crafters.

Final word

As you can see, CNC machining is present in every industry. Whatever the manufacturing business you are in, you will need a machine that will suit your requirements.