Your car’s clutch plays a vital role in the smooth operation of your vehicle, allowing you to smoothly shift gears and maintain control while driving. Clutches, like any mechanical part, can, however, wear out with time and develop problems that impair driving and performance. In this guide, we’ll take a closer look at some common clutch problems, their causes, and how to address them to keep your vehicle running smoothly on the road.

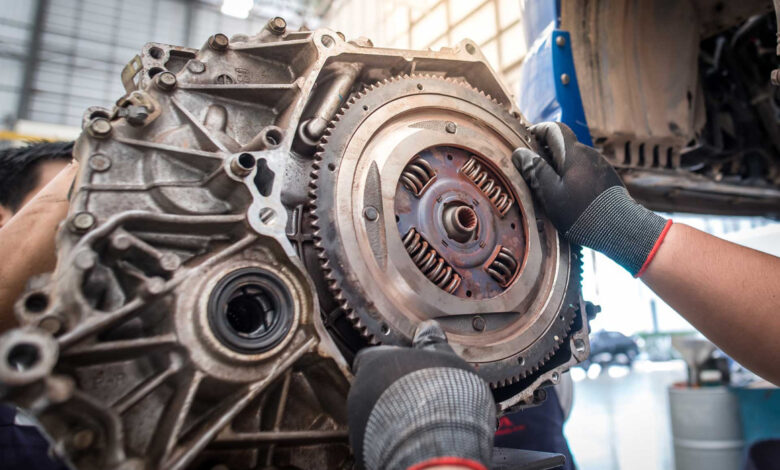

Understanding Your Clutch System

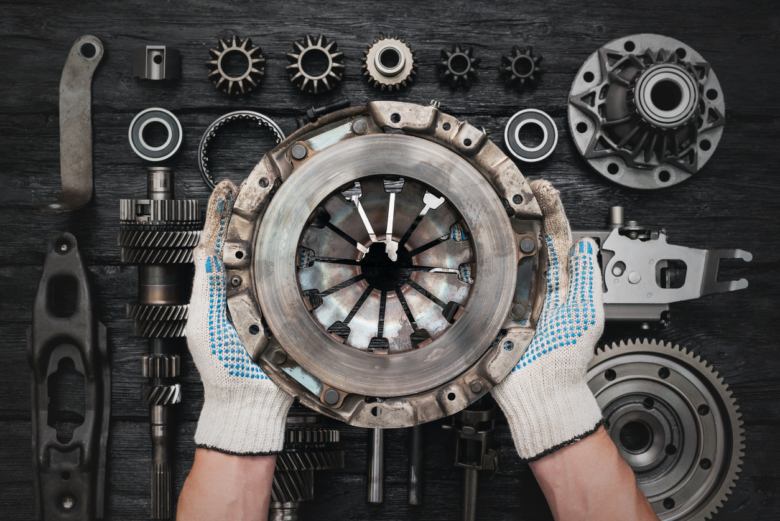

Source: hars.com.tr

Before we dive into diagnosing clutch issues, let’s first understand how the clutch system works. You can shift gears smoothly because the clutch links and disconnects the engine from the transmission. The clutch is disengaged and the engine and gearbox are separated when you depress the clutch pedal. This eliminates the need to grind or harm the gearbox while changing gears.

Identifying Common Clutch Issues

- Slipping Clutch: A slipping clutch is one of the most common issues drivers encounter. You may notice that the engine revs increase without a corresponding increase in vehicle speed, or the clutch pedal feels spongy or loose. This could indicate worn clutch discs or pressure plate springs, causing the clutch to slip under load.

- Clutch Drag: Clutch drag occurs when the clutch fails to disengage fully, resulting in difficulty shifting gears or a grinding noise when shifting. This could be caused by issues with the clutch hydraulic system, such as low fluid levels or air bubbles in the hydraulic lines.

- Clutch Chatter: Clutch chatter is characterized by a vibration or shuddering sensation when engaging the clutch, especially when starting from a stop. This could be caused by a warped or damaged flywheel, worn clutch components, or improper clutch adjustment.

- Clutch Pedal Issues: If you experience problems with the clutch pedal, such as a soft or spongy feel, difficulty engaging or disengaging the clutch, or the pedal sticking to the floor, it could indicate issues with the clutch hydraulic system, such as a leaky master or slave cylinder.

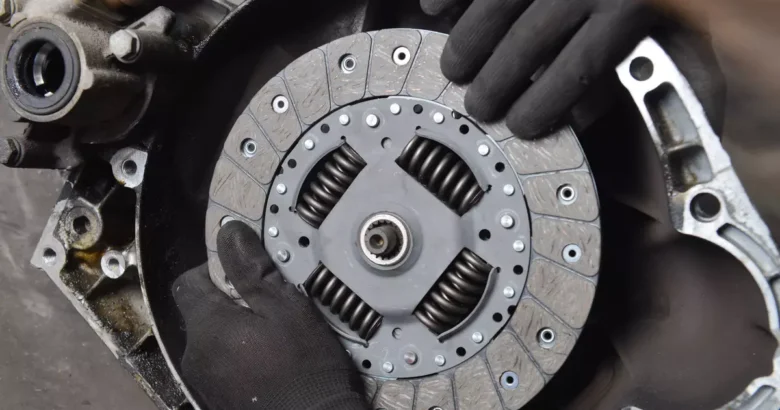

Diagnosing and Fixing Clutch Problems

Source: haynes.com

- Check Clutch Fluid: Start by checking the clutch fluid reservoir to ensure it’s filled to the recommended level. Low fluid levels could indicate a leak in the hydraulic system, which should be addressed immediately to prevent further damage.

- Inspect Clutch Components: If you suspect a slipping clutch, worn clutch discs, pressure plate springs, or a damaged flywheel may be the culprit. Inspect these components for signs of wear or damage and replace them as needed.

- Adjust Clutch Pedal: If you’re experiencing issues with the clutch pedal, such as a soft or spongy feel, it may be necessary to adjust the clutch pedal height or free play. Consult your vehicle’s owner’s manual for instructions on how to adjust the clutch pedal properly.

- Bleed Clutch Hydraulic System: If you suspect air in the clutch hydraulic system is causing clutch drag or pedal issues, bleed the system to remove any air bubbles and ensure proper clutch operation.

Advanced Clutch Maintenance and Preventive Measures

Source: levrettauto.com

Beyond understanding and diagnosing common clutch issues, it’s crucial to adopt a proactive approach to clutch maintenance. Regular maintenance can help extend the life of your clutch system and ensure your vehicle operates smoothly. Here are some advanced tips and preventive measures to keep your clutch in top shape.

Regular Inspection and Maintenance

- Routine Inspections: Regularly inspect your clutch system as part of your vehicle’s maintenance schedule. Look for any signs of wear, such as thinning clutch discs, weakened pressure plate springs, or fluid leaks. Early detection of potential problems can prevent costly repairs and ensure your vehicle remains safe to drive.

- Clutch Fluid Maintenance: Just as with your engine oil or brake fluid, maintaining the proper clutch fluid level is vital. Check the clutch fluid regularly and top it off as needed. Use the type of fluid specified in your vehicle’s owner’s manual, and change the fluid according to the manufacturer’s recommendations to ensure optimal performance.

- Check for Leaks: Periodically check the clutch master and slave cylinders for leaks. Fluid leaks in these components can lead to clutch failure or difficulty shifting gears. Replace any leaking components immediately to avoid further damage.

Driving Habits to Extend Clutch Life

- Smooth Shifting: Avoid aggressive driving habits such as rapid acceleration or shifting gears abruptly. Smooth, gradual shifting reduces the stress on the clutch components and minimizes wear and tear.

- Avoid Riding the Clutch: Resting your foot on the clutch pedal while driving, known as “riding the clutch,” can cause premature wear. Use the clutch only when necessary, such as during gear changes, and keep your foot off the pedal when cruising.

- Proper Use of Clutch in Traffic: In heavy traffic, it’s tempting to keep the clutch partially engaged while creeping forward. Instead, use the clutch fully—either fully engaged or fully disengaged—to prevent unnecessary strain on the clutch system.

- Downshifting Techniques: Avoid downshifting to slow down the vehicle unless necessary. Use your brakes for deceleration and downshift only when it’s beneficial for vehicle control or when approaching a stop.

Upgrading Clutch Components

- High-Performance Clutches: If you frequently drive in demanding conditions or use your vehicle for performance purposes, consider upgrading to a high-performance clutch. These clutches are designed to handle higher loads and provide better durability under stress.

- Reinforced Clutch Kits: For heavy-duty applications or towing, reinforced clutch kits offer improved strength and longevity. These kits often include upgraded pressure plates, stronger clutch discs, and enhanced flywheels.

- Hydraulic System Upgrades: Upgrading the clutch hydraulic system can enhance clutch responsiveness and reliability. High-quality master and slave cylinders, along with stainless steel hydraulic lines, can provide more consistent clutch operation.

Clutch Replacement and Professional Assistance

- Know When to Replace: Even with proper maintenance, clutches will eventually wear out and need replacement. Common signs that indicate the need for a new clutch include persistent slipping, difficulty shifting, or a burning smell during gear changes.

- Professional Inspection: If you’re unsure about the condition of your clutch system, seek professional inspection. Experienced mechanics can diagnose clutch problems accurately and recommend the best course of action.

- Quality Parts and Service: When replacing clutch components, opt for high-quality, OEM (Original Equipment Manufacturer) parts. While aftermarket parts may be cheaper, OEM parts ensure compatibility and longevity. Additionally, choose a reputable service center for clutch repairs to guarantee expert installation and adjustment.

Conclusion

Source: auto.howstuffworks.com

Maintaining a properly functioning clutch is essential for safe and smooth driving. By understanding common clutch issues and how to diagnose and address them, you can keep your vehicle running smoothly on the road. If you’re unsure about diagnosing or fixing clutch problems yourself, it’s always best to consult a qualified mechanic or clutch repair specialist to ensure the job is done correctly. With proper care and maintenance, you can enjoy trouble-free driving for miles to come.