Cryogenic cables are the semi-rigid cables for low temperatures. They consist of low thermal conductivity metal materials on center and outer conductors. use a variety of metals with an ultra-low rating for thermal conductivity such as NbTi, Nb3Sn, MgB2, BSCCO-2212, BSCCO-2223, and ReBCO. This extremely low thermal conductivity of cryogenic cable prevents low external temperatures from affecting the performance of the cabling. It also allows for extremely high current to run through a relatively small cross-section with minimal electrical losses.

These factors allow cryogenic cables to work in situations where traditional cabling would fail. Whether you need slim cables in tight spaces or in environments with extremely low external temperatures, the cryogenic cable provides a solution. This allows cryogenic cabling to be used in a wide variety of applications with very little restraints. The most common uses for cryogenic cable includes microwaves, medical, scientific, defense, aerospace, and computer science, according to delft-circuits.com.

What is Cryogenic Microwave Cable?

Img source: thejakartapost.com

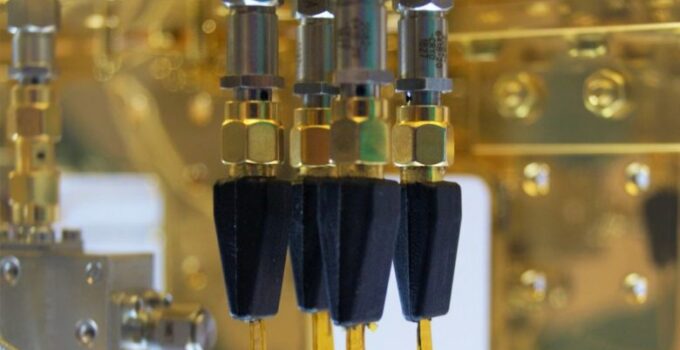

Cryogenic microwave cable is a specially designed type of cryogenic cable made for handling microwave frequencies. To successfully handle microwave frequencies in a cryogenic setup, the cryogenic cable requires a special combination of both thermal and microwave properties. This balance can become difficult to achieve in order to allow a cryogenic setup to operate smoothly.

Microwave setups using cryogenics also typically operate in extremely confined spaces. This requires a cable with high levels of flexibility and a small cross-section while still delivering the current required of the setup. With a growing number of devices needed to operate at low temperatures, the form factor becomes an important issue. This requires a cable with high levels of flexibility and a small cross-section while still delivering the current required of the setup. While typical coaxial cryogenic cables can have a good microwave performance, their form-factor and the thermal load cannot satisfy the growing number of low-temperature electronics operations.

Typical coax cables simply cannot successfully fulfill this need due to the wear from multiple bending cycles and high failure rates. However, specific types of cryogenic cables designed for microwave setups fulfill this need offering high flexibility, durability, and a small cross-section. while still allowing affordable microwave performance for high currents. They also operate well with microwave frequencies in the temperatures of typical cryogenic microwave setups.

What is Cryogenic RF Cable?

Img source: elspecgroup.de

RF cables are typically coaxial cables designed to send radio frequency signals in a commercial setting. However, applications for radio frequency signals in extreme environments exist which can require cabling that fits the needs of the environment. In a cryogenic setting, cryogenic RF cable can be used. Cryogenic RF cables provide a high-performance solution in settings with minimal space or extremely low temperatures.

These requirements exist in a wide variety of applications, but particularly in the aerospace and aviation field. They require a reliable means of communication without interruption regardless of the temperatures. Cryogenic RF cables fulfil this need while also allowing for the cabling to work in tight spaces.

What is Cryogenic Multi-Channel Ribbon Cable?

Img source: delft-circuits.com

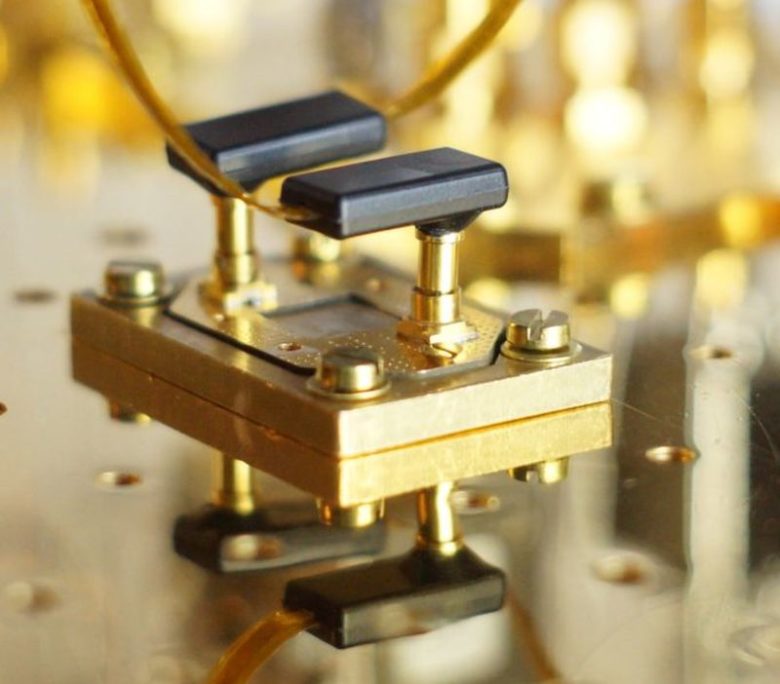

The multi-channelRibbon cable consists of multiple conducting wires running parallel to each other creating a wide and flat cable. They are typically used in the internal peripherals of a computer for higher speed connections due to the use of multiple conducting wires working together. However, multi-channel ribbon cables frequently interfere with computer cooling due to the wide shape interrupting airflow. This especially becomes a problem in cryogenic setups when that airflow can reach extremely low temperatures which reduces the performance of the cable.

Cryogenic multi-channel ribbon cable solves this problem for cryogenic setups by allowing functionality in extremely low temperatures. Oftentimes these types of computers utilize a liquid cooling solution to keep the temperatures of the computer extremely low. This is particularly true when using any type of cryogenic processor which requires cryogenic cables for success. These processors generally operate at temperatures reaching as low as -27337500°CF which would significantly reduce the effectiveness of traditional cabling. So, the cryogenic multi-channel ribbon cable allows for effective connections for any type of setup that requires ultra-low internal temperatures and microwaves high currents.

How Cryogenic Cabling is Used in Industrial Applications

Img source: delft-circuits.com

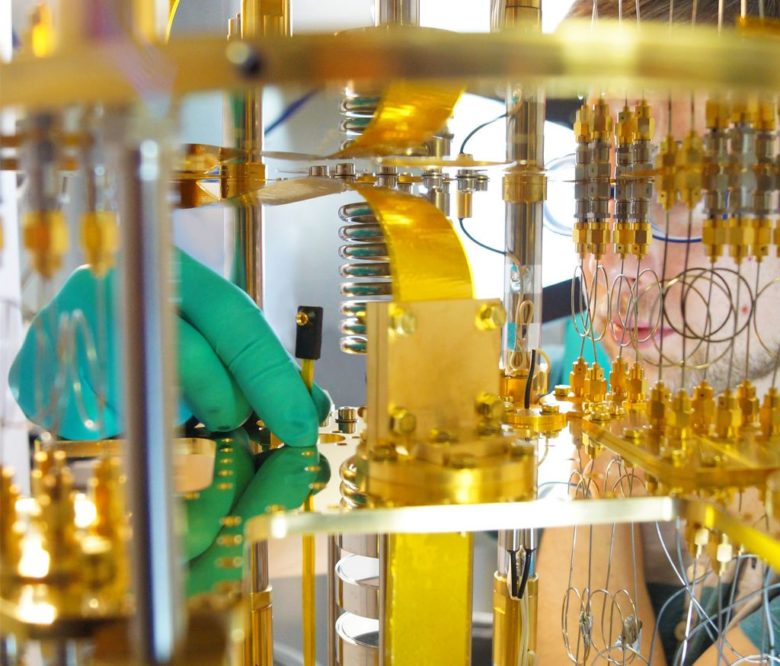

One of the most common uses for cryogenic cabling is within the space of quantum computers. Quantum computers rely on operating in extremely low temperatures due to the use of superconducting elements in the processor.to prevent the computer from overheating due to the heavy processing it performs. This requires specially designed cooling solutions, such as liquid cooling, to prevent overheating and components that can operate at these extremely low temperatures. They usually utilize cryogenic processors and other cryogenic components to maintain a low operating temperature. These extremely low temperatures of 10 mK require cabling that still operates effectively which is where cryogenic cabling comes into play.

The cryogenic cable is also used in quantum internet applications. Instead of utilizing radio frequencies (RF)waves to transmit information, quantum internet uses delicate photons of infrared light to transmit information. This allows for higher speed transmissions at a higher capacity. However, it typically relies on special electronics quantum satellites to receive and transmit information. These satellites operate at extremely low temperatures which require the use of cryogenic cables for successful, uninterrupted operations.

Another use of cryogenic cables is within cryogenic microwaves. Cryogenic microwaves allow for an extremely high powered microwave. These systems rely on maintaining extremely low temperatures throughout operations in order to prevent failure. They typically use either a mechanical refrigerator or Dewars to maintain their low temperatures. Regardless of the cooling mechanism, cryogenic cables are required at the extremely low temperatures cryogenic microwave operate in.

Why Delft Circuits is Better Than Other Companies

Img source: gigabitmagazine.com

Delft Circuits produces specially designed cryogenic cables made for specific applications. Through the use of Cri/oFlex® technology, Delft Circuits is able to provide flexible cryogenic cabling suitable for most cryogenic applications. This cabling allows for operations at ultra-low temperatures and a scalable cryogenic i/o solution. Cri/oFlex® provides excellent microwave performance, low thermal load, flexibility, and reliability.

The high levels of flexibility of Delft Circuits’ Cri/oFlex® cable make it easy to install in any situation. This particularly comes into play for cryogenic microwave cabling as cryogenic setups are typically tight on space requiring a highly flexible cable. It also makes for simpler installation in any other cryogenic setup.

This technology of Cri/oFlex® cable also allows for the building of quantum computers that require many communication channels. Delft Circuits achieve this through their scalable i/o solution allowing you to utilize any number of communication channels that you require.

Cri/oFlex® is specifically designed for any application where thermal load, microwave performance, noise characteristics, small form factor, and phase stability are critical to success.