As a manufacturing method, CNC machining for medical devices provides greater certainty in the design and production phases to deliver a great final result. When implants or surgical instruments aren’t completed to the right standard, falling short can have dire consequences. There was a reason for the introduction of these, therefore, it should be natural for the manufacturers to make the equipment complement with standards. Only by following them carefully, we can expect devices to be as efficient as we want them to be.

CNC machining proved pretty efficient in these fields therefore it is not a surprise why they are considered as a standard. There are some things that you need to be aware of. So, if you are interested in this topic, be sure to check out marshallmfg.com. Here are 5 reasons to use CNC machining specifically when dealing with the manufacturing of medical devices, equipment, or instruments.

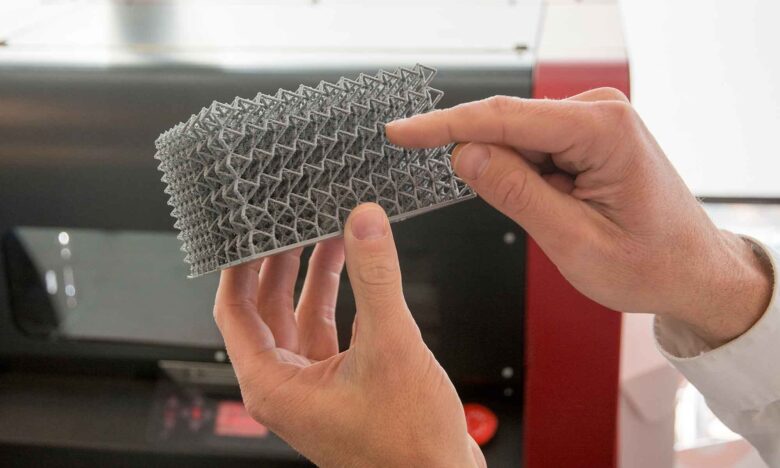

Exacting Needs of Medical Implants

Source: theconversation.com

Some medical equipment that is implanted inside the patient is required to complete the surgery successfully. Their use might be to replace a destroyed bone, to support a failing joint or for other medical purposes that are intended to improve the health and happiness of the patient.

Implants must be produced to an exacting standard. Indeed, there must be conformity between each implant. Not only does this ensure that the part will fit perfectly where it’s intended to go, but it provides predictable results for both surgeons and patients.

The CNC wire EDM manufacturing process can deliver finished products with all the necessary holes, grooves, and other aspects matching the computerized design. The cutting implements provide a .0005” to an inch accuracy to create a medical product that’s imperceivable different to the naked eye to the previous one.

True Customization for Unusual or Custom Requirements

Source: twitter.com

CNC machines are programmable to create exactly what’s required to match the varied needs of the medical profession. These are a pretty complex machine that requires a set of skills from every person operating on them.

The machines are computer-controlled to use exact movements from the original source material. Cutting out various shapes allows for specific molding of the initial workpiece. Implementing a square shape at the top, a cylindrical hole lower down or another shape is just a matter of getting the design right and letting the machine do its thing.

The sophistication of the programming method allows for complicated final designs that are perfected in the software first and then transitioned through the physical machining process. Parts may be machined as one-off items for a single patient or in a limited run.

As you are perfectly aware, every person has its own set of requirements when it comes to healthcare. Every one of us has our own needs, so creating a device that serves only one purpose is out of the question. Thankfully, CNC machining offers us the possibility of creating devices for different needs and produce them quickly.

Durability for Successful Surgeries

Source: discoverbenelux.com

Medical parts are produced using CNC machining to be exceptionally durable. There are a couple of reasons for this. The main reason is the material that’s used for the creation of these devices. At the same time, the precision of the CNC machines is exceptionally high, so we can see that there are no irregularities on them.

Given that the final product will be used to help sick patients, to support their bodies, and depending on the part, may get implanted – they must be built to last. This is one of the most important questions of having proper CNC-made devices, the question of their benefits to the health condition of every human being.

A good example of this is with hip replacement surgery. These parts must be an exact fit, smooth, and durable. Recovering from a hip replacement requires months of healing and discomfort. The last thing anyone wants is to go through a second operation because a part failed, broke off, or didn’t function as required.

Ease of Sterilization for Surgical Instruments

Source: biznisgroup.rs

Surgical instruments used in the operating theater such as forceps, clamps, saws, cutters, and handles all play an important role in allowing surgical staff to complete an operation. Naturally, since this kind of device is done for the purpose of being used in the medical industry, they need to be sterilized and being sterile, will be more efficient and will prevent potential irregularities.

Equipment must be sterile. The use of titanium alloys and surgical steel along with surfacing technologies allows medical instruments to be used reliably and sterilized to avoid accidental infection of a patient. In the healthcare profession, there’s little margin for error. To be precise, there should be none, but the perfect device doesn’t exist. Medical instruments and implants must be durable, produced to an exacting standing, and able to withstand scrutiny. Nothing less will do.

Comfort and Safety

Source: agro-chemistry.com

We know that there is a wide array of medical implants that are saving countless lives of people every day. At some point in time, their size was too large for the human organs. Thankfully, with the precision of CNC machines, we can see that now we are able to create devices of the proper size that will provide much more safety and comfort to the people who are actually in need of them.

Since their size is lowered and the comfort level is increased, it should be said that now we have multiple options who are all of the great quality. These are placed directly inside the body of a person and provides the necessary care for a particular organ or system in our organism. Comfort is an essential element in this case since the patient will carry it inside of its organism and there is no question about that.

The Takeaway

Source: trends.medicalexpo.com

CNC machines really provide us with a wide array of possibilities when it comes to creating devices and machines that can be used in the healthcare industry. We’ve presented you with 5 reasons why CNC machining is a perfect way of producing these devices. We are pretty certain that this is not just a trend that will fade over time. Instead, they are here to stay for a long time, with some improvements if needed.