Nowadays, it is almost impossible to imagine our life without using devices that make our lives easier. PCBs are very important components of hardware technology. Without them, modern technology would not work, and therefore their presence is inevitable. Prototyping is a very important part of the development of most modern products.

Therefore, making a PCB prototype is significant as it greatly simplifies the process. Of course, working with specialized PCB companies is far more reliable, convenient and cost-effective. This way you will also know that quality is guaranteed.

PCB Is A Highly-Developing Industry

The traditional PCB consumer electronics industry is a labor-intensive industry. With the development of auto electronics, 5G and other technologies, high density, and high performance have become the main directions of development of printed circuit board technologies. Market demand for high-quality PCB products (such as flexible boards, HDI boards, IC mounts, etc.) is steadily increasing, and the gross profit margin of these high-tech products is also higher, bringing higher profits for businesses.

The data shows that global PCB production is accelerating due to increased demand. According to statistics, global PCB production in 2017 was more than 58 billion dollars. Among them, PCB production in China amounted to almost 30 billion dollars. By 2024, the global PCB industry is expected to be worth over 60 billion dollars.

Img source: circuitspecialists.com

Best Things About PCB Prototype

There are many advantages to using PCB services. These are some of the best things about PCB prototype.

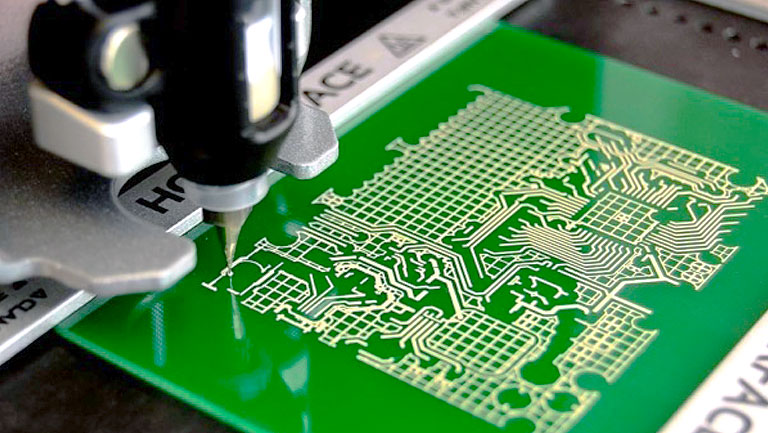

1. Better Quality Prototypes

Expert manufacturers have huge experience. They use their knowledge and expertise in the PCB manufacturing industry. PCB companies are well acquainted with the developments and trends within this industry. They can significantly improve the quality of the product and adapt it to market conditions. When working with a PCB manufacturing service, you’ll be gaining everything – from prosperous CNC-machinery, through high-quality materials, to expertise in making prototypes. If Check out https://www.pcbonline.com/PCB-FAB/PCB-prototype for a prototype example.

2. Faster Turn-Around-Time

Using specialist company services can help you if you’re looking for faster turnaround times when producing prototypes. Specialized PCB companies know how important deadlines are and they can understand market demands. Therefore, these companies have extensive processes in manufacturing and production improving. Reliable PCB companies take this quite seriously since this can help reduce the time of the PCB prototype production.

Img source: pixabay.com

3. Affordability And Cost-Effectiveness

Speaking of the cost-effectiveness when manufacturing of PCBs – it is a key factor. Working with a specialized PCB company will help you reduce your investment costs. PCB manufacturers are usually very flexible when manufacturing the product. Therefore, they are a perfect business partner even for companies with a limited budget. For those who are looking to manufacture PCB prototypes themselves, large capital investment will be needed at the very beginning. That type of investment requires high-quality materials, equipment, a certified workforce, etc.

4. PCB Solutions In One Place

It is the best option to use the services of one PCB company. This way you will avoid outsourcing. Though some companies think outsourcing will cut down their costs, that is not true. What’s more, it’s counter-productive. Besides, having more providers can bring problems such as bad coordination between suppliers, etc. Therefore, one-place-solution will be the best choice.