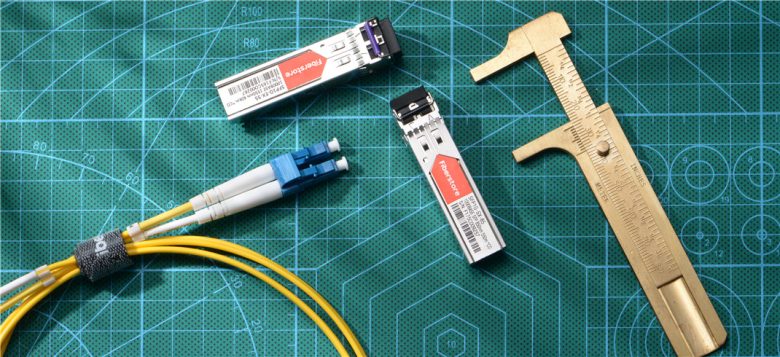

Optical modules is a major research hotspot in the field of optical communication technology. High speed, miniaturization, and low power consumption are the development trends of optical modules, while high reliability is the basic requirement of practical communication systems and networks for practical optical modules. The research on reliability analysis and testing technology of high-speed broadband optical modules plays an important role in promoting the development level and market competitiveness of optical devices. This paper will study the reliability of the 100G high-speed optical transceiver module (click here).

What is the reliability of optical modules

Reliability is defined as “the ability of a product to perform a specified function under specified conditions and within a specified period of time”.

“Specified conditions” refers to the use environment and maintenance conditions of the product. For electronic components, “specified conditions” mainly refer to working conditions (such as voltage, current and power used), environmental conditions (such as temperature, humidity and air pressure, etc.) or storage conditions during use. These conditions will have an impact on the failure of the product, and the reliability of the product will vary under different conditions. Therefore, evaluating the reliability of a product must specify conditions.

Source: community.fs.com

“Scheduled time” means the time when the product performs the task. Generally speaking, the reliability of electronic components will gradually decline with the prolongation of use and storage time. The reliability of the same component varies according to the specified time. Therefore, reliability must specify reliability over how long.

“Prescribed function” refers to the technical requirements and technical indicators of the product. Since each product has different roles and functions in the system, the product is considered reliable if it fulfills the specified functional requirements; otherwise, it is unreliable. The ability to perform a function, usually expressing a qualitative requirement for reliability. The probability of completing a function, usually a quantitative requirement for reliability, is a measure of the magnitude of reliability.

100G Optical Module Reliability Related Standards

Since the advent of the 100G network, IEEE, the Multi-Source Agreement (MSA) Industry Alliance and other organizations have formulated multiple standards for 100G modules. Among the many standards, the 100G SR4, PSM4 and CWDM4 standards formulated by the MSA industry organization are more suitable for the mainstream 100G QSFP28 optical modules on the market. The following table shows the specific conditions of some common 100G optical module standards:

| Standard | Connector & Cable Type | Transmission Distance |

| 100GBASE-SR10 | 24 Fiber MPO, Parallel MMF, 850nm | OM3,100m OM4,150m |

| 100GBASE-SR4 | 12 Fiber MPO, Parallel MMF, 850nm | OM4,100m |

| 100GBASE-LR4 | Duplex LC, SMF, 1310nm, 4x25G WDM | SMF, 10km |

| 100GBASE-ER4 | Duplex LC, SMF, 1310nm | SMF, 40km |

| 100G PSM4 | 12 Fiber MPO, Parallel SMF, 850nm | SMF, 500m |

| 100G SWDM4 | Duplex LC, MMF, 850-950nm, 4×25G SWDM | OM3, TBD WBMMF |

| 100G CWDM4 | Duplex LC, MMF, 1271-1331nm, 4×25G CWDM | SMF, 2km |

| 100G CLR4 | Duplex LC, SMF, 1271-1331nm, 4×25G CWDM | SMF, 2km |

Optical module reliability test and analysis

Semiconductor laser accelerated life test

Because semiconductor lasers are usually used in high-speed systems and are threshold devices, it is known by derivation and experiments that their temperature stability is poor. In the test, in order to consider the influence of the working environment temperature on the reliability and life of the semiconductor laser, the temperature control function was not added to the drive circuit. At the same time, in order not to introduce other possible failure mechanisms, a slow-start function is designed for the drive circuit, so as to prevent damage to the semiconductor laser caused by voltage overshoot during the test. The aging test was carried out by current acceleration, thermal acceleration and current-thermal dual stress acceleration to explore the effect of stress on the degradation of the operating characteristics of semiconductor lasers.

Accelerated life test of high-speed optical modules

For high-speed optical modules, in order to study the relationship between their life and temperature and current stress, the optical modules are operated in different environments and current stresses, and their performance changes are compared. Before and after the accelerated life, the relevant performance parameters of the optical module are measure and compared. For many performance parameters of optical modules, from the perspective of use and information transmission, the most important basic performance parameters are average optical power, bit error rate, receiving sensitivity, and eye diagram.

(1) Average optical power detection

Source: en.wikipedia.org

The average transmitted optical power of an optical module is the average optical power when the optical module transmits a light source through a series of pseudo-random signals to intensity-modulate the optical module under normal conditions, and is output through the pigtail of the optical fiber. In the test, the pseudo-random signal can be input to the transmitting end of the optical module through the bit error meter, and then observed through the optical power meter.

(2) Receive sensitivity detection

Receiving sensitivity is a key factor to measure the quality of an optical module. The receiving sensitivity refers to the minimum received optical power that the receiving end can receive under the condition that a given bit error rate (Bit Error Ratio, BER) requirement is met. First, a pseudo-random signal of a certain code pattern is sent out through the bit error tester, and the signal is connected to the electrical interface of the optical module through a high-speed line. The bit error rate is monitored by high-speed line input back to the bit error tester. At the same time, an adjustable optical attenuator (VOA) and a splitter (OC) will be added to the output end of the transmitting end. By adjusting the transmitting optical power, the transmitting optical power will continue to decrease until it reaches the critical point of bit error, but the bit error is guaranteed. If the rate is within the limited bit error rate, the optical power meter is used to measure the transmitted optical power value after attenuation, and this value is the receiving sensitivity.

(3) Eye diagram

Source: viavisolutions.com

The quality of the signal transmission of the optical module can be visually observed through the eye diagram, and the eye diagram can be observed through the bit error tester. After adjusting the period of the random pseudo-sequence received and sent by the bit error tester to be consistent, the superimposed pattern of various periodic random sequences can be collected through the eye diagram function of the bit error tester. Because the final pattern is very human-like. eyes, so it is called the “eye diagram” figuratively. Large “eye”: the gap between the eyes is large, and the eye diagram is relatively correct, indicating that the intersymbol interference and noise of the signal are small, and the system transmission characteristics are good; the “eye” is small: the gap between the eyes is small, indicating that the signal There is inter-symbol interference and the noise is large, and the transmission characteristics of the system are not very good.